Full Servo Automatic Hot Foil Stamping Machine For Plastic Cosmetic Tube

Description:

Full Servo Automatic Hot Foil Stamping Machine For Plastic Cosmetic Tube

Mode:AH-60240

Printing Size: Φ(16-60)*(50-240)

Printing speed: 50-80 pcs/min

Pessure: 5-7 bar

Net weight: 1500kg

Machine size: 355L*160W*180H(cm)

Voltage: AC380V 50/60Hz 15Kw

Features:

This equipment is adopted fully servo-control, with which is the technological innovation of the traditional pneumatic machine.

1. Faster operating speed: the operating speed could increase to 40% at 80PCS/Min comparing with the traditional machine.

2. Higher accuracy: the stamping accuracy could be controlled within 0.1mm, almost zero error executing order instructed by the presets parameter

3. More perfect effect: the hot-stamping head could be designed into 7 segments with different pressure according to the thickness of picture, which could perfect the picture.

4. More accurate position: the fully operating process controlled by the Vacuum adsorption to ensure the accuracy of the stamping after the left-and-right, forward-and backward position.

5. Intelligently dividend test: this machine sets with Qualified and unqualified channel, the unqualified products will be automatically sorted out from the unqualified channel.

6. Easier operation: Just need to change the channel position, touché and adjust the corresponding parameters to adopt the product with different channel diameter.

Full Servo Automatic Hot Foil Stamping Machine For Plastic Cosmetic Tube

Mode:AH-60240

Printing Size: Φ(16-60)*(50-240)

Printing speed: 50-80 pcs/min

Pessure: 5-7 bar

Net weight: 1500kg

Machine size: 355L*160W*180H(cm)

Voltage: AC380V 50/60Hz 15Kw

Features:

This equipment is adopted fully servo-control, with which is the technological innovation of the traditional pneumatic machine.

1. Faster operating speed: the operating speed could increase to 40% at 80PCS/Min comparing with the traditional machine.

2. Higher accuracy: the stamping accuracy could be controlled within 0.1mm, almost zero error executing order instructed by the presets parameter

3. More perfect effect: the hot-stamping head could be designed into 7 segments with different pressure according to the thickness of picture, which could perfect the picture.

4. More accurate position: the fully operating process controlled by the Vacuum adsorption to ensure the accuracy of the stamping after the left-and-right, forward-and backward position.

5. Intelligently dividend test: this machine sets with Qualified and unqualified channel, the unqualified products will be automatically sorted out from the unqualified channel.

6. Easier operation: Just need to change the channel position, touché and adjust the corresponding parameters to adopt the product with different channel diameter.

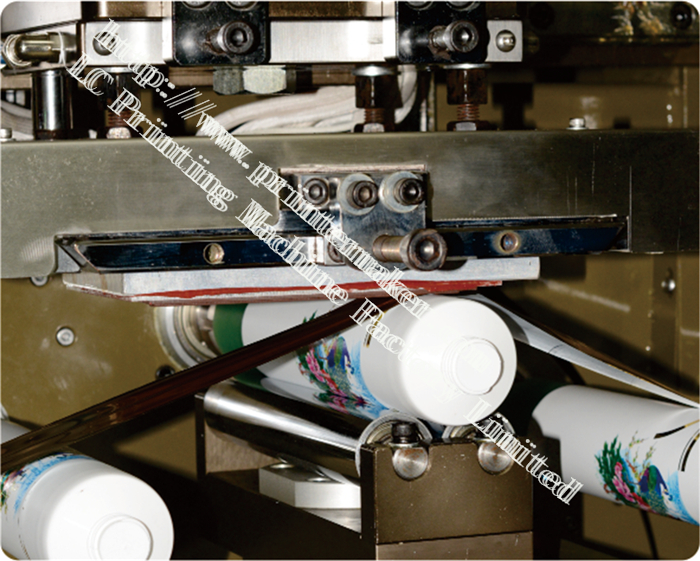

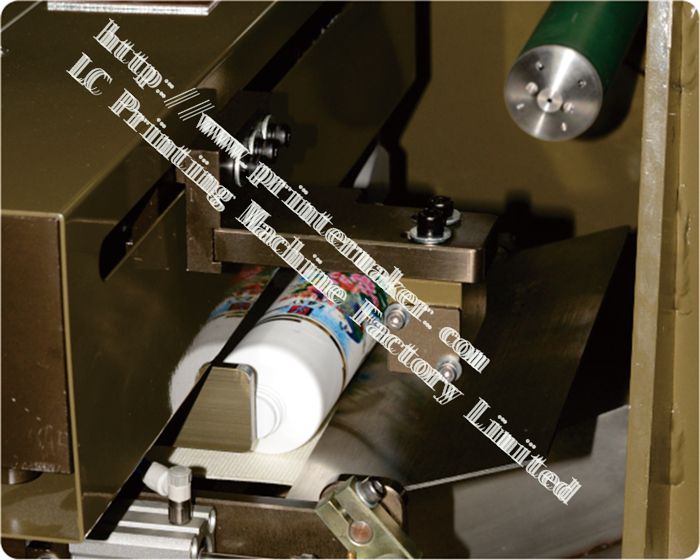

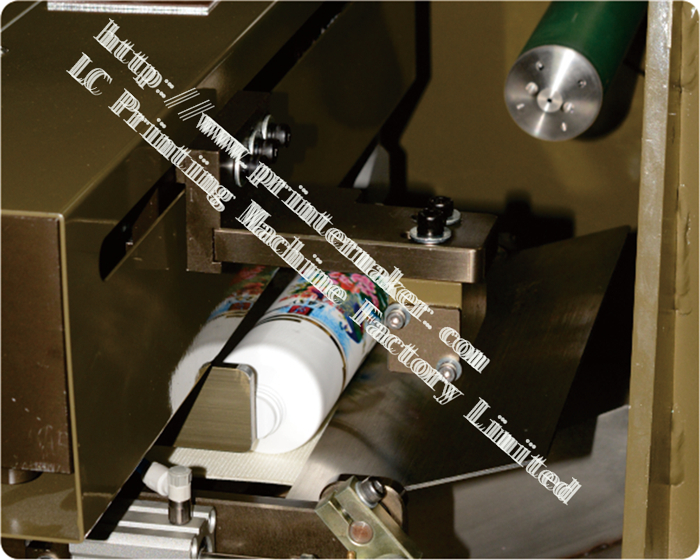

Printing Samples:

Write your message here and send it to us